Royal Caribbean's Symphony of the Seas has 23 dining venues onboard, serving around 30,0000 dishes daily. On busy weeks, there are almost 9,000 people (guests and crew) that need to be fed. More than 2,000 kilos of potatoes are consumed each day, as well as over 6,000 kilos of beef, more than 8,000 kilos of chicken, and 10,000 dozens of eggs per seven-day cruise. From chefs to dishwashers, a team of 1,850 people keeps passengers fed. And this is how it looks behind the scenes.

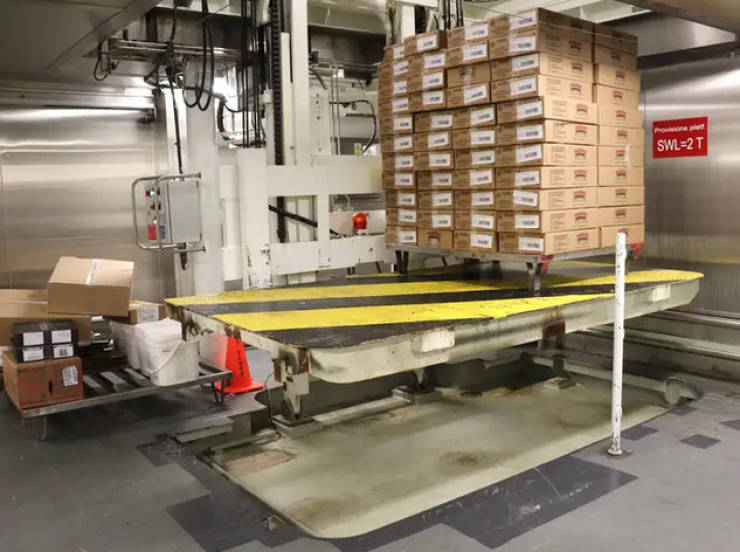

Thirty tons of food are delivered in Miami every Saturday, ahead of a seven-day cruise on Royal Caribbean's Symphony of the Seas, according to the ship's inventory manager Jaret de Silva.

"On average, we load every Saturday 500 pallets, and we need to finish by 4 p.m. in time to sail away from Miami," he told Insider. "It's a big logistic requirement."

Usually, around two extra days of food is loaded onto the ship in case of an emergency, which is upped to three days during hurricane season.

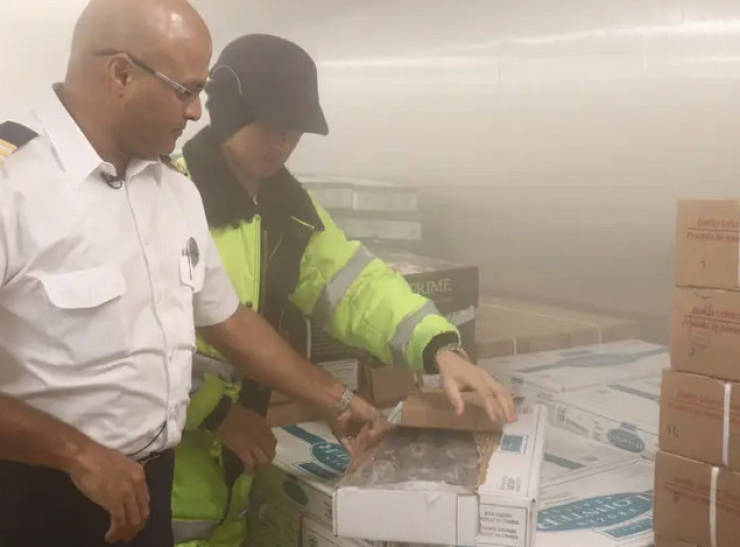

"It's a hectic process," he puts it mildly, explaining that food needs to be strictly temperature controlled, and cannot sit outside for more than five to seven minutes.

All the food is inspected ahead of loading, and if it doesn't meet his standards it won't even be allowed on the ship.

Once onboard, a team of 18 people make sure food is divided into the appropriate store rooms.

There are 20 store rooms, ranging in temperature from freezers to dry storage.

There are fridges for seafood, meat, vegetables, and fruit.

All this happens on a super long corridor deep inside the ship that passengers don't have access to.

It's known as the I-95, after the interstate highway between Maine to Key West, Florida, and super busy.

Once stored, the food "belongs" to de Silva. "It is my ownership. I own everything," he said, explaining that chefs must place their food orders with him and his team.

Once chefs place their orders, food is prepped.

Fish is scaled, cut, and thawed.

Veggies are chopped.

Orders are then placed in special rooms where chefs can pick them up.

Orders must be placed at least a day in advance, to give meat and fish time for a natural thawing process.

While most of the cooking is done the day a dish will be served, preparation starts the day before.

The bakery makes 40 different kinds of bread from scratch.

And the pastry kitchen makes 100 different types of desserts, from cake pops to strawberry mousse.

Each of the 12 specialty restaurants on the ship has its own kitchen. There are three more for the main dining room, as well as three kitchens where food is prepared to serve all the restaurants onboard.

Eight chefs work the day shift and another eight work the night shift just prepping dishes.

Food is being prepared 24/7.

In total, the ship has 285 working chefs. There are four chefs making nothing but sauces, and another six entirely focused on soups.

Sixteen of them chop vegetables.

From chefs to dishwashers and waiters, a team of 1,850 people keeps passengers fed.

The main dining room has a different menu every night, each with around eight entrees to choose from. It feeds around 900 people at a time, and between 3,000 and 4,500 people a night.

The specialty restaurants feed around 150 people at a time and have set menus that remain the same every night, but together also offer 350 different dishes daily.

Menus are tweaked slightly based on customer feedback, but generally they remain the same having been developed by Royal Caribbean at its Miami headquarters months in advance.

Executive Chef German Eladio Rijo Rijo does a food tasting at 4 p.m. every day.

The weekly food orders are also mostly constant, though these can change depending on the expected demographic onboard. For example, the holiday season sees around 2,000 kids onboard, making more kid-friendly meals a must.

"Sometimes you get a demographic entirely from, let's say Europe. So the eating habits change. So certain recipes or certain dishes that are offered may not be liked by other demographics. So the chef will not use them and we need to adjust our orders," said de Silva.

One of the hardest parts of feeding passengers is that chefs must cater to guests with very different tastes, from passengers who are spending $50,000 a night on suites and want lobster and truffles to families who want nothing but mac and cheese and pizza.

De Silva's team checks the quality of the food every day to see if it needs to be used earlier than planned. For example, broccoli ripening faster than expected could become a broccoli soup.

Generally, little is thrown out and leftovers are scarce. The world's largest ship is a well-oiled machine after all.

2. by unnecessary stuff i mean not only food, but the whole concept of it.

3. those kind of ships are a lot bigger enviromental problem than cars.